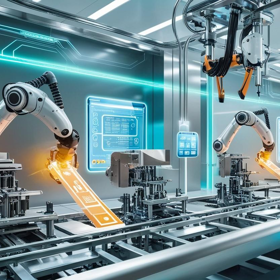

Industry 4.0 is transforming manufacturing, and digital twins are at the heart of this shift—connecting the physical and digital worlds to minimize inefficiencies, reduce waste, and prevent downtime. In this challenge, you’ll design a smart digital twin of an industrial production line (e.g., a drawing product manufacturing system) using cutting-edge tools like Siemens NX MCD, TIA Portal, and AI-driven algorithms.

Based at INSA Strasbourg’s Factory of the Future—a high-tech lab equipped with NIRYO robots, PLCs, and IoT sensors—you’ll tackle real-world Industry 4.0 challenges while collaborating with peers and industry experts.

Why join?

- Develop industry-ready skills: Gain hands-on experience with Siemens NX, AI-driven predictive maintenance, and automation—expertise that top employers like Siemens are looking for.

- Solve real challenges: Optimize energy use, automate logistics, and improve precision in stamping processes using real-time sensor data.

- Boost your career prospects: Build a portfolio-ready digital twin prototype to showcase your ability to innovate in smart manufacturing.

From September to January, you’ll take part in hybrid workshops to prototype your system, test solutions with robots and PLCs, and pitch your ideas to industry leaders. No prior Siemens NX experience? No problem—training and datasets are provided. All you need is curiosity and a willingness to collaborate.

By the end, you won’t just understand Industry 4.0—you’ll help shape its future. Join a global community of innovators and gain the confidence to transform factories into smarter, more sustainable hubs of tomorrow.

Are you ready to lead the Industry 4.0 revolution?

To find out more about our department at INSA Strasbourg, follow the link below:

https://genie-electrique.insa-strasbourg.fr/